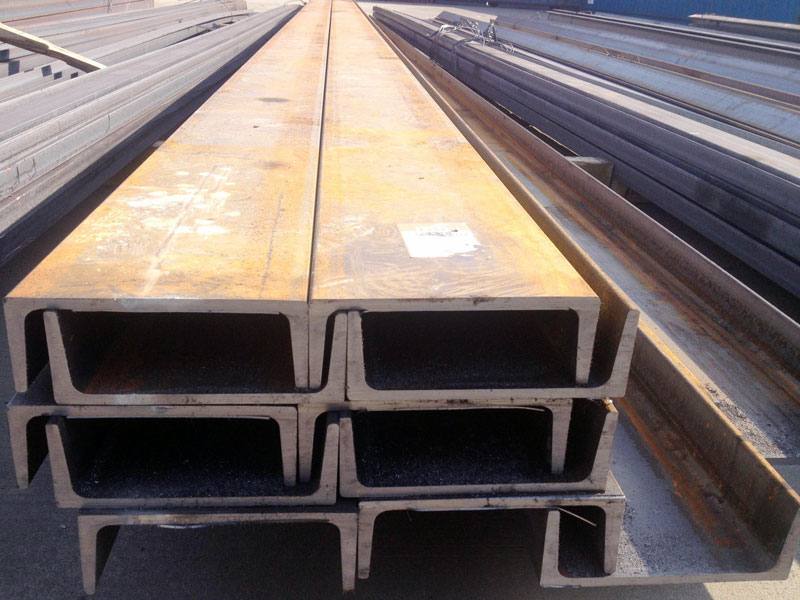

Hot-rolled C Beam is automatically processed and formed by a C channel steel forming machine. The C channel forming machine can automatically complete the C channel forming process according to the given C channel size.

Galvanized C Beam, hot-dip galvanized cable tray C Beam, glass card slotC Beam, glass curtain wall C Beam, cable trough C Beam, reinforced C Beam, double hug C Beam, single-sided C Beam, manual forklift C Beam, Unequal side C Beam, straight-side C Beam, hypotenuse C Beam, inner-curved C Beam, inner beveled C Beam, roof (wall) purlin C Beam, automobile section C Beam, highway column C Beam, solar support C Beam (21-80 series), template supporting C Beam, precision C Beam for equipment, etc.

| Production name | Hot-rolled C Beam |

|---|---|

| Specification | GB: 50-300 (5#-30#) |

| TYPE | Carbon profile steel |

| Style No. | Size (mm) | Weight | ||

|---|---|---|---|---|

| H | B | D | Kg/m | |

| 5 | 50 | 37 | 4.5 | 5.438 |

| T 0 | ||||

| (30b) | 300 | 87 | 9.5 | 39.173 |

GB/T700: Q235

GB/T1591: Q345

ASTM A36, ASTM A283, ASTM A572

EN0025-2: S235JR, S355JR

JIS G3101: SS400,SS490

JIS G3106: SM400, SM490

DIN17100: ST37-2, ST52-3

| Size(mm) | Weight (kg/m) | Size(mm) | Weight (kg/m) |

|---|---|---|---|

| 50*37*4.5 | 5.438 | 220*77*7.0-A | 24.999 |

| 63*40*4.8 | 6.634 | 220*79*9.0-B | 28.453 |

| 65*40*4.8 | 6.709 | 250*78*7.0-A | 27.41 |

| 80*43*5.0 | 8.045 | 250*80*9.0-B | 31.335 |

| 100*48*5.3 | 10.007 | 280*82*7.5-A | 31.427 |

| 120*53*5.5 | 12.059 | 280*84*9.5-B | 35.823 |

| 126*53*5.5 | 12.318 | 300*85*7.5-A | 34.463 |

| 140*58*6.0-A | 14.535 | 300*87*9.5-B | 39.173 |

| 140*60*8.0-B | 16.733 | 320*88*8.0-A | 38.083 |

| 160*63*6.5-A | 17.24 | 320*90*10.0-B | 43.107 |

| 160*65*8.5-B | 19.752 | 360*96*9.0-A | 47.814 |

| 180*68*7.0-A | 20.174 | 360*98*11.0-B | 53.466 |

| 180*70*9.0-B | 23 | 400*100*10.5-A | 58.928 |

| 200*73*7.0-A | 22.637 | 400*102*12.5-B | 65.204 |

| 200*75*9.0-B | 25.777 |

Hot-rolled C Beam is widely used in the purlins and wall beams of steel structure buildings, and can also be combined into lightweight roof trusses, brackets and other building components. In addition, it can also be used for columns, beams and arms in light machinery manufacturing.