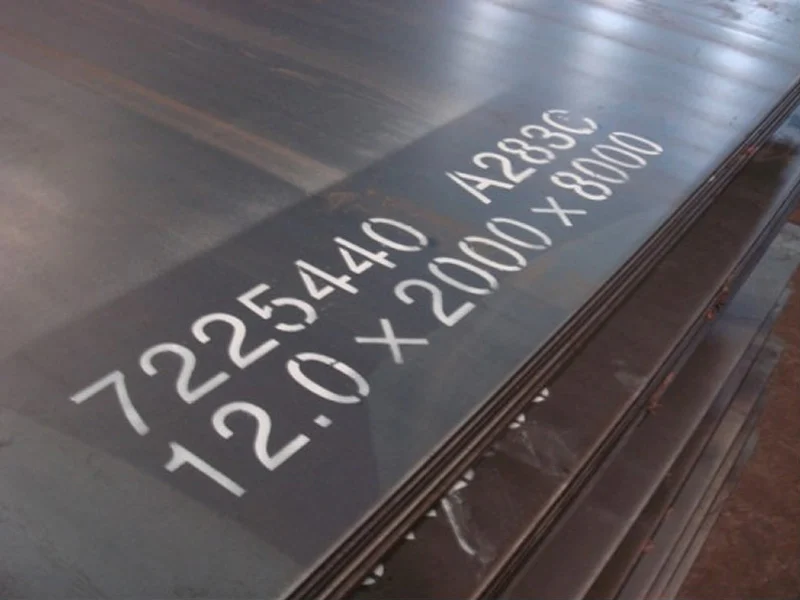

ASTM A283 Grade C

ASTM A283 Grade C introduction

ASTM A283 is a standard specification for low and intermediate tensile strength carbon steel plates of structural quality for general applications. ASTM A283 Grade D is a versatile and widely used steel grade for various structural and construction projects.

ASTM A283 Grade D steel Applications:

Buildings and bridges, Tanks and pressure vessels, Ships and offshore structures, General fabrication and construction

ASTM A283 Grade D steel Welding:

ASTM A283 Grade D steel is weldable using various methods, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). Preheating and post-weld heat treatment are not typically required for thinner plates, but may be recommended for thicker plates or critical applications.

ASTM A283 Grade D steel Corrosion Resistance:

ASTM A283 Grade D steel has moderate corrosion resistance and can be used in environments with mild atmospheric corrosion. However, it is not recommended for severe corrosion environments, such as marine applications, without additional corrosion protection measures, such as galvanizing or painting.

ASTM A283 Grade D steel Advantages:

- Versatile: Suitable for a wide range of structural and construction applications

- Good Strength: Provides adequate strength for various load-bearing applications

- Weldable: Easily weldable using different methods

- Cost-Effective: Relatively economical compared to higher-strength steel grades

ASTM A283 Grade D steel Limitations:

- Moderate Corrosion Resistance: Not suitable for severe corrosion environments without additional protection

- Lower Strength: Compared to high-strength steel grades

ASTM A283 Grade C general

| Property | Temperature | Value |

|---|---|---|

| Elongation A200 | 23.0 °C | Elongation A200 of 22 % |

| Elongation A50 | 23.0 °C | Elongation A50 of 25 % |

| Tensile strength | 23.0 °C | Tensile strength of 380 - 515 MPa |

| Yield strength | 23.0 °C | Yield strength of 205 MPa |

ASTM A283 Grade C chemical

| Property | Value |

|---|---|

| Carbon | Carbon of 0.24 % |

| Copper | Copper of 0.2 % |

| Manganese | Manganese of 0.9 % |

| Phosphorus | Phosphorus of 0.03 % |

| Silicon | Silicon of 0.4 % |

| Sulfur | Sulfur of 0.03 % |

Let our steel inspire you to innovate, create, and excel in your industry.

-- Our promise

Get a quote